Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

With the development of laser technology, its application in various industries is also increasingly widespread, playing an increasingly important role in many fields. For example, the laser marking machine, which is now widely used in the industrial field, is one of the indispensable processing methods for many products. Laser marking has the characteristics of high quality, high efficiency, environmental protection and low cost. Compared with traditional marking or marking processing methods, it can greatly improve production efficiency and production quality and open up broad prospects for modern processing and production.

There are more and more types of laser marking machines, and the applicable materials and marking effects of different types will be different. So, how do you know which model is suitable for your product? Next, Foshan Fulan Laser will briefly introduce several laser marking machines commonly used in industry.

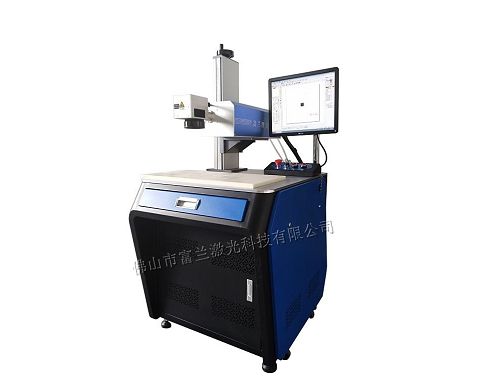

The first type: fiber laser marking machine

Fiber laser marking machine is a more mature laser marking machine equipment, which is mainly used for marking with metal materials and some non-metallic materials with higher ignition points and harder materials. The fiber laser marking machines produced by Foshan Fulan Laser Technology Co., Ltd. are equipped with high-speed digital scanning heads, and the marking speed is 2-3 times that of traditional models; the electro-optic conversion rate is as high as 30%, and the power consumption is traditional models It is about 10%; it is cooled by air cooling, the whole machine is small and compact, with long life, easy maintenance, and high beam quality.

The second type: UV laser marking machine

Mainly used in the high-end market of ultra-fine processing, 3C industry marking, marking of electronic components, electrical enclosures, marking of packaging bottles for food, medicines and other polymer materials; removal of metal or non-metallic coatings; marking of various materials, blind Groove treatment; new ultra-thin metal foil micro-hole production, etc. The beam quality is good, the focusing spot is smaller, and the ultra-fine marking can be achieved. The heat-affected area is extremely small, no thermal effect, and no material scorching problem. The scope of application is wide. All materials except copper are applicable.

The third type: CO2 laser marking machine

CO2 laser marking machine is mainly used for non-metallic materials, such as: leather, cloth, wood, bamboo products, plastic, rubber, PVC and so on.

The fourth: green laser marking machine

Mainly used in 3C industry marking, white goods, electrical shell marking, flight marking of food and pharmaceutical production dates, etc.; metal or non-metallic coating removal; scoring of various materials, blind groove treatment; emerging Ultra-thin metal foil micro-hole production, etc. It also has a special name: laser internal engraving machine, which can be used for surface and internal engraving of glass and crystal products. Stable power output, superior beam quality, making marking more fine and clearer; semi-cold light source, small heat-affected area; wide range of applicable materials, making up for many materials that are not delicate enough with fiber laser marking and have poor results problem.

Fifth: MOPA laser marking machine

Mainly used for aluminum alloy, anodized aluminum black marking, aluminum oxide sheet surface stripping, electronics, semiconductor, ITO precision processing, stainless steel color marking, deep carved metal, plastic and other sensitive materials and PVC plastic pipe industry marking.

Laser marking equipment does not depend on the price or type, but whether it meets the production needs of enterprises.