Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

1. What is a laser marking machine?

Laser marking machine (laser marking machine) is also called "laser engraving machine, laser machine, laser engraving machine, laser machine, laser coding machine, laser engraving machine, laser marking machine, laser marking machine, etc.". It uses laser The beam is permanently marked on the surface of various materials.

The effect of marking is to use high-energy-density lasers to locally irradiate the workpiece. The physical evaporation of the surface material exposes the deep material, or the chemical and physical changes of the surface material caused by light energy to "carve" traces, or light energy Burn off part of the material to reveal the pattern and text to be etched.

Second, the principle of laser marking processing

1. Basic principles:

The laser emitted by the laser undergoes a series of processing, and the energy is concentrated in a small range after being focused by the lens, so that the surface material is instantly melted or even vaporized. By controlling the path of the laser on the surface of the material, the required image is formed. Text mark.

According to different material properties (such as melting point, boiling point, temperature at which chemical change occurs), the workpiece will undergo a series of physical or chemical changes, such as melting, vaporization, oxide formation, discoloration, and so on. This is the principle of laser processing.

2. Recognized principle:

Cold processing: photons with high load energy can modify the material or the surrounding medium to cause non-thermal process damage to the material. Because the low temperature is used, the thermal ablation temperature of the bottom of the box is lower, so there is no "thermal damage" side effect to achieve cold peeling, so there is no heating or thermal deformation on the inner layer and nearby areas of the processed surface, nor will it affect The workpiece causes problems such as burning, black edges, and deformation. Green laser marking machine and UV laser marking machine belong to cold processing.

Thermal processing: The surface of the workpiece is irradiated with a high-energy laser beam. The surface of the material absorbs laser energy and generates a thermal excitation process in the irradiated area, so that the temperature of the material surface (or coating) rises, causing metamorphosis, melting, ablation, evaporation, etc. . In order to achieve our final target effect, it is called thermal processing because high temperature is used to achieve the desired effect. Fiber laser marking machine, co2 laser marking machine, semiconductor laser marking machine belong to thermal processing。

3. Laser processing mode

The focused laser is like a very thin invisible tool, which vaporizes the surface of the local area of the object point by point. It is characterized by non-contact processing and does not touch the workpiece. It can be marked on any special-shaped surface without producing Mechanical extrusion or mechanical stress will not change the physical properties of the processed article; due to the small size after laser focus, the small heat-affected area, and fine processing, some processes that cannot be achieved by conventional methods can be completed.

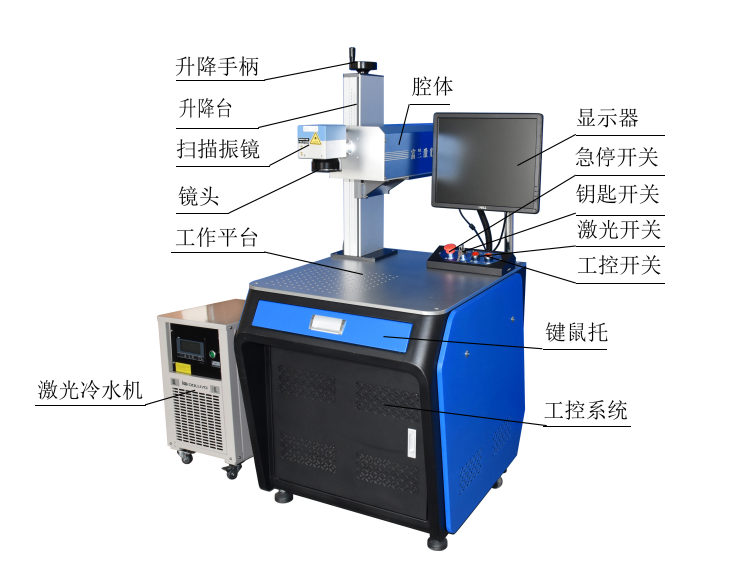

Fourth, the composition of the laser marking machine

Mainly composed of laser power supply, laser, marking control software, galvanometer field lens scanning system, focusing system, industrial computer, cabinet (Note: specific, depending on the model, different models, components will be different) .

Five, the advantages of laser marking machine

1. The mark is permanent: the mark is not easy to imitate and change, and it will not fade due to environmental relations (touch, acid and alkaline gas, high temperature, low temperature, etc.).

2. Non-contact processing: Laser marking is processed by a non-mechanical "light knife", the workpiece will not produce internal stress after marking, and the original accuracy of the workpiece is guaranteed.

3. High marking precision: the articles marked by the laser marking machine are beautiful and delicate, and the markings are fine, clear, durable, beautiful and good in hand.

4. Wide application range: It can be applied to marking almost any material.

5. Low operating cost: The laser marking machine can mark in one step, with fast marking speed and low energy consumption, without consumables, so the operating cost is low.

6. High processing efficiency: The laser marking machine is controlled by an industrial computer. The laser beam under computer control can move at a high speed, and the marking process can be completed in a few seconds.

7. Fast editing and development: Any content can be marked and edited at will.

8. Flexible configuration: it can meet the requirements of commercial small batch or single (semi-automatic) processing, and also meet the requirements of industrialized assembly line (fully automated) mass production.

9. Consistent effect: ensure that the processing effect of different batches of the same product is completely consistent.

10. Environmental protection: Laser marking is non-contact marking, which saves energy and avoids chemical pollution compared with corrosion method. Compared with mechanical marking, it can also reduce noise pollution.

6. Classification of laser marking machine

1. Classified by laser: CO2, semiconductor, YAG, optical fiber, green light, ultraviolet, mopa.

2. Classification by wavelength: ultraviolet (355 nm), green light (532nm), lamp pump YAG (1064nm), semiconductor YAG (1064nm), optical fiber (1064nm), mopa (1064nm), CO2 (10.64um).

3. Classified by style: handheld, desktop, online, desktop, portable, other styles (non-standard equipment customized according to customer requirements).

Seven, the use of laser marking machine

1. Dot: The dot light guide plate marked by laser is not easy to yellow, has high illumination, uniform light guide, and lasting effect.

2. Punching: Laser drilling has simple requirements for workpiece clamping, and it is easy to realize on-line and automation on the production line. Laser drilling can be carried out on various materials such as hard, brittle, soft, etc., with fast processing speed and high precision, and the hole wall surface is smooth and without burrs.

3. Laser-engraved light-transmitting characters: It can engrave light-transmitting effects on sprayed objects with transparent substrates such as plastic, glass, acrylic, etc., not only without any damage to the smooth surface of the product, but also with extremely clear light transmission. The laser marking machine launched by Foshan Fulan Laser has the characteristics of fast engraving speed, long service life, simple operation, zero consumables, high precision, safety and environmental protection and zero pollution, and the engraved characters and patterns have long-lasting color and no falling off.

4. Engraving: Use the heat energy of the laser to engrave the material. The surface of the engraved part is smooth and round; it can be widely used for engraving on various non-metal and metal materials (the depth of engraving depends on the material being marked).

5. Cutting easy to tear lines: The laser marking machine independently developed and produced by Foshan Fulan Laser is a more advanced and flexible technology that concentrates the micron-sized laser energy on the surface that needs to be scribed for processing. Energy will not cause any damage to other films or even the entire film. Whether it is a solid line or a dashed line, or a different scribe line shape, it can be easily realized!

6. Hollowing: The existing laser technology can completely hollow out and engraving on thin sheets of various materials. The laser marking machine produced by Fulan Laser adopts high-speed digital scanning head, which is small in size, fast in speed, good in stability, dynamic focusing, wide processing width, suitable for any graphics processing, and compatible with various drawing software. Bitmap, scribing, cutting, and hollowing can be done at one time, with no yellow edges and no paste edges.

7. Marking: The laser marking machine can mark on products of any material. The marking is clear and fine, with unique visual and tactile effects and the characteristics of never being wiped, so it has strong anti-counterfeiting and anti-sweeping characteristics , It can also improve the grade of the product while preventing counterfeiting.

8. Marking and cutting integration: Flan Laser's existing laser marking equipment can achieve both marking and cutting on one product.

9. Laser burning: The laser marking machine effectively combines computer-aided design technology to perform artistic finishing on denim fabrics. The high-energy laser beam makes the dye on the surface of denim fabrics vaporize or fade away instantaneously. The fabric is formed with non-fading image patterns, gradual flower shapes, cat whiskers, frosted, broken holes and washed for old effects. Due to the high degree of controllability of the laser, many personalized color-discharging printing effects can also be achieved.

10. Removal of the plating or coating on the surface of the workpiece: After the workpiece is electroplated or sprayed, the laser marking machine can remove the plating or coating on the surface, leaking the original background color. Whether the removal is clean or not has a certain relationship with the uniformity of the thickness of the electroplating layer or sprayed layer, the configuration of the laser equipment and the technology.

In addition to the above-mentioned uses, laser marking has many other uses. For details, please consult Fulan Laser customer service.

8. Operation process of laser marking machine

1. Boot steps:

① Turn on the main power switch;

②. Insert the key switch and turn it clockwise 90 to the "on" position;

③ Turn on the industrial control switch, and the industrial control computer will automatically start;

④ Turn on the power switch of the computer monitor and the host computer;

⑤ Don't turn on the emergency stop switch (that is, the switch bounces up, it is in an automatic closing state);

⑥ Turn on the key switch, turn on the laser switch, and turn on the laser marking software;

2. Marking operation:

① Open the marking software;

②. Select the marking file→Open→Select the file to be marked (or create a new and edit the graphic to be marked);

③. Alignment: click the "red light" at the bottom of the mouse, the laser head will emit a red box to shoot on the marking part, move the workpiece to make the box fall on the part to be marked, and then click to stop the "red light" after adjustment, and then Fix the tooling. (Note: You must be quick when aligning, and the red light should not be used for too long, so as not to shorten the life of the light-emitting head.)

④ Focusing: Place the workpiece template at the place to be marked, then check the continuous marking, mouse click "Continuous Machining", then click "Marking", shake the handle to adjust the Y-axis lift until the laser acts on the energy of the workpiece When the strongest, the sharpest sound, and the brightest color, it is basically the focal length. (The editor of Foshan Fulan Laser here kindly reminds you: "Continuous processing" is only used for focusing. After the focus is adjusted, please remember to turn off "Continuous processing" before operating.)

⑤ After the trial engraving is OK, you can press the "Mark (F2)" key to start marking.

The above is the first time to mark a marked part. The pages including graphics and marking parameters should be saved as a file, and the height of the laser head and the marking surface should be measured. The file will be recalled from the computer and directly checked during the next production. If the height is high, it can be marked.

3. Shutdown steps:

① After confirming that the industrial computer is not running any software, close the laser marking software;

② Turn off the industrial control and water and electricity systems in sequence;

③. Turn off the main power switch after the computer has a black screen and shut down;

④. Remove the key and keep it by someone for the next use;

⑤. Close the lens cover.

Fulan Laser has always focused on the field of laser equipment,

——to provide you with the most suitable laser equipment.