Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

Laser marking machines can be divided into cold processing and thermal processing. These two processing technologies are mainly for different materials. Generally, thermal processing is for materials that can be heated. On the contrary, cold processing is for materials that cannot be heated.

Next, the editor of Foshan Fulan Laser will discuss with you the cold processing and thermal processing of laser marking machines.

Cold processing: photons with very high load energy can modify the material or the surrounding medium to cause the material to undergo non-thermal process damage. Because the low temperature is used, the thermal ablation temperature of the bottom of the box is lower, so there is no "thermal damage" side effect to achieve cold peeling, so there is no heating or thermal deformation on the inner layer and nearby areas of the processed surface, and it will not The workpiece causes problems such as burning, black edges, and deformation.

For example, green laser marking machine and ultraviolet laser marking machine belong to cold processing.

Thermal processing: The surface of the workpiece is irradiated with a high-energy laser beam. The surface of the material absorbs the laser energy and generates a thermal excitation process in the irradiated area, thereby increasing the temperature of the surface (or coating) of the material, causing metamorphosis, melting, ablation, evaporation, etc. . In order to achieve our final target effect, it is called thermal processing because high temperature is used to achieve the desired effect.

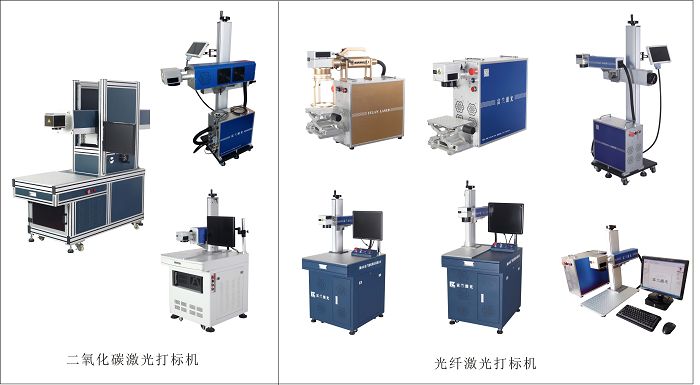

Such as: fiber laser marking machine, CO2 laser marking machine, mopa laser marking machine and semiconductor laser marking machine belong to thermal processing.