Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

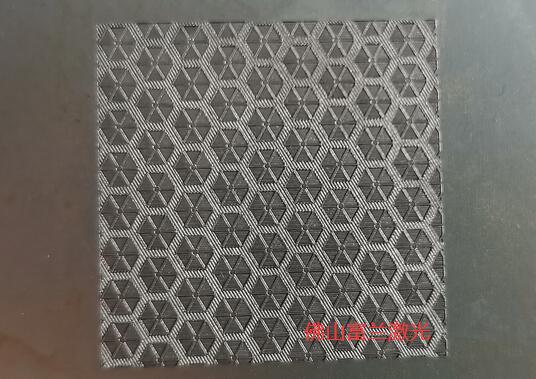

The laser marking machine, from the name of the equipment, seems to be only used for marking, but in fact it has a wide range of uses. It can be used for marking a variety of materials, marking light guide plates, marking easy-to-tear lines, burning fabrics, perforating thin materials, cutting thin materials, stripping coatings from electroplating spray parts, engraving glass crystals, etc. It can also be used for The mold bites the flower and the sun pattern. Next, please follow Foshan Fulan Laser to understand the advantages of laser tattooing.

1. The texture marks are permanent: the textures marked by the laser are not easy to imitate and change, and will not fade due to environmental relations (touch, acidic and alkaline gases, high temperature, low temperature, etc.);

2. Non-contact processing: Laser marking is processed with a non-mechanical "light knife", which does not corrode the surface of the workpiece, has no "tool" wear, is non-toxic, and has no pollution;

3. High precision of lines: The patterns of the items marked by the laser marking machine are beautiful and delicate, fine and clear, and have a good feel. The need to engrave a large amount of data on the workpiece;

4. Low operating cost: The laser marking machine can mark one-time forming, the marking speed is fast, the energy consumption is low, and no consumables are required, so the operating cost is low;

5. Simple operation: no experience is required, and it can be learned in about 2 hours (Foshan Fulan Laser will conduct one-to-one training for customers until it is learned);

6. High processing efficiency: The laser marking machine is controlled by an industrial computer, the laser beam under the control of the computer can move at high speed, and the marking process can be completed within a few seconds;

7. The production cycle is extremely short, and the editing and development speed is fast: both marking;

8. Any content can be marked and edited immediately: the combination of laser technology and computer technology, all the information to be marked is edited in real time by the computer, as long as it is programmed on the computer, the laser printing output can be realized, and the printing can be changed at any time. content of the design manuscript;

9. Can freely control the depth of engraving;

10. Environmental protection: Laser marking is non-contact marking, which saves energy, does not require the use of chemical agents such as strong acid and alkali, and does not produce industrial waste such as mask tape and acid solution used for etching.

11. The process is simple and fast: the laser texture processing process: degreasing and washing mold → drawing → laser processing → glossy treatment.

The emergence of laser marking texture processing technology has brought innovation to the surface processing of molds. Everything is possible with the perfect combination of digital texture design and laser marking technology. From the digital computer design to the generation program, the fidelity of any graphic texture can be guaranteed, and then imported into the laser marking machine for processing, and the laser is used for fine processing to realize the distinctive appearance of the product and transform the infinite imagination of the product appearance. come true.