Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

Laser marking machine is a common industrial manufacturing and processing equipment. In order to enable our customers to quickly and correctly use the laser marking machine equipment, Foshan Laser has organized a detailed and easy-to-understand user guide for your reference. Note: The operation process will be slightly different for different models, depending on the actual model.

1. Before starting:

Before starting, please clean the work surface, check whether the laser marking machine is safely grounded, and check the power cord of the marking machine to make it connected correctly and reliably.

2. Start-up steps:

①, turn on the main power switch (after the power is turned on, the work indicator is always on and the fan is running);

②. Insert the key switch and turn 90 clockwise to the "on" position;

③, turn on the industrial control switch, the industrial control computer starts automatically;

④, turn on the power switch of the computer monitor and computer host;

⑤ Do not turn on the emergency stop switch (that is, the switch bounces upward, it is automatically closed);

⑥. Turn on the key switch, turn on the laser switch, and turn on the laser marking software;

⑦. Take off the protective cover of the laser galvanometer;

⑧, adjust the relevant parameters of the software for laser marking.

3. Marking operation:

① Open the marking software;

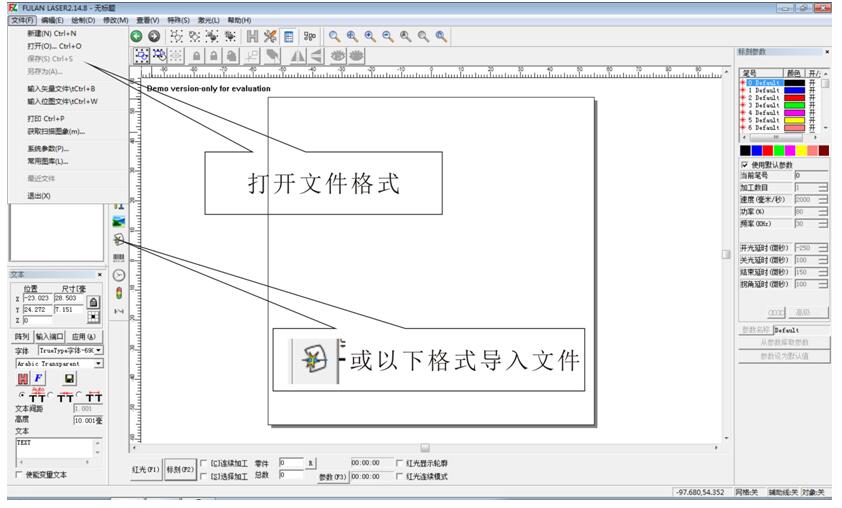

②, select the marking file → open → select the file to be marked (or the graphic to be marked by the new editor);

③, Alignment: click the "red light" below the mouse, the laser head emits a red frame to shoot on the marking piece, translate the workpiece to make the frame fall on the position to be marked, adjust it and click to stop the "red light", then Fix the tooling. (Note: The alignment should be quick, and the time of using the red light should not be too long, so as not to shorten the life of the light emitting head.)

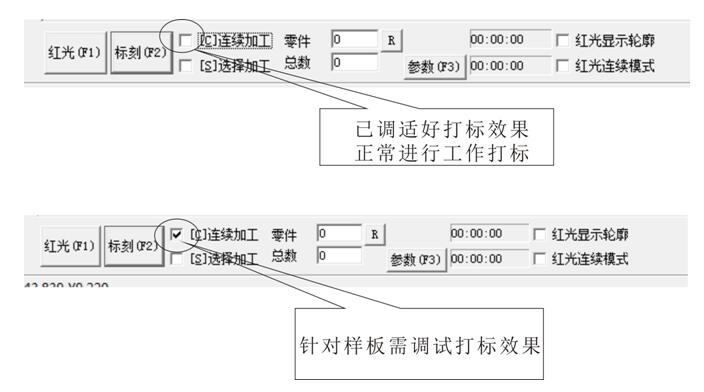

④ Focusing: Place the workpiece template at the position to be marked, then tick continuous marking, click "Continuous Processing" with the mouse, then click "Marking", shake the handle to adjust the Y-axis up and down until the laser acts on the workpiece energy The strongest, the clearest sound, and the brightest color is basically the focal length. (Foshan Fulan Laser Editor here warmly reminds you: "Continuous processing" is only used when adjusting the focus. After adjusting the focal length, please remember to turn off "Continuous processing" before operating.)

PS: The manual focusing head is slow and inefficient because of manual focusing, and the accuracy of the focusing is not guaranteed, so that many waste products are produced; for this reason, Foshan Laser Technology Co., Ltd. is autonomous according to market needs. Developed a system-automatic focusing system. Automatic focusing system can be configured in any laser marking equipment, please contact Fulan Laser customer service for details.

⑤ After the trial engraving is OK, you can press the "Mark (F2)" key to perform the marking work. (Mark multiple workpieces, just repeat this step).

The above is the first marking of a marking piece. The page including graphics and marking parameters should be saved, and the height of the laser head and the marking surface should be measured. The file will be called from the computer and directly aligned during the next production. Good height, you can mark.

Four, shutdown steps:

① After confirming that the industrial computer is not running any software, close the laser marking software;

②, turn off the industrial control and hydropower system in sequence;

③, turn off the laser switch, and then turn off the key switch;

④, turn off the computer;

⑤ After the black screen of the computer shuts down, turn off the main power switch;

⑥. Remove the key and keep it by a special person for the next use;

⑦. Put on the lens cover.

5. Maintenance of laser marking machine:

1. Keep the workplace and equipment clean;

2. Open the case of the marking master computer every year to clean the internal dust;

3. When moving the laser marking machine, be careful not to damage the laser delivery tube;

4. The laser moves the components up and down, check the lubrication once every six months;

5. Don't install software irrelevant to work randomly, and clean up the internal files of the computer every six months;

6. Operate strictly according to the start-up steps of the equipment, and do not operate indiscriminately;

7. When the device is working, it is strictly forbidden to open any end cover;

8. The laser and optical lens are fragile, and should be handled with care when handling, and avoid vibration;

9. Water-cooled, the cooling water must be pure, non-sticky, and often replaced;

10. If there are any abnormalities during the operation, the equipment should be shut down immediately, and personnel should be arranged to inspect and maintain the equipment. Please note: Repairs should be carried out by qualified personnel or authorized personnel of the equipment supplier.

11. The fluctuation of the power supply grid should be less than 10%. If it cannot be guaranteed, a voltage stabilizer must be installed.

If you buy a laser marking machine, you will find Foshan Fulan Laser. Factory direct sales, free proofing, on-site installation, one-to-one training, one-year warranty and lifetime maintenance.