Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

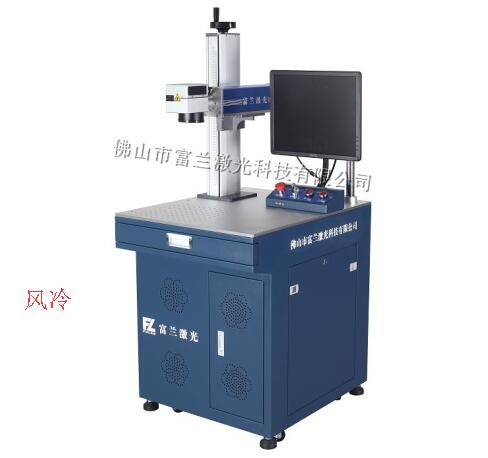

Why are some laser marking machines air-cooled while others are water-cooled? Next, Fulan Laser will explain to you: the difference and precautions between water cooling and air cooling for laser marking machines.

1. The difference:

In fact, the functions of water cooling and air cooling are the same. They both cool the machine transmitter and the Q drive to ensure the normal operation of the laser equipment.

The cooling method adopts water cooling or air cooling, mainly depends on the power of the equipment itself. Generally, high-power laser equipment (optical fiber, carbon dioxide above 50W), the heat emitted by the laser is relatively large, so it is cooled by circulating water, and the disadvantage of water cooling is that it is relatively large. However, because of the low power, the power is relatively small (basically not more than 50W), so the heat of the laser is not large, and air cooling can be used for cooling, which not only condenses the volume of the equipment, but also reduces the energy consumption of the equipment.

2. Matters needing attention:

1. Regardless of whether it is water-cooled or air-cooled, the dirt inside the water tank or fan should be removed, and a regular cleaning work should be done. This will not only have a good operability for the equipment, but also greatly improve its life, ensuring that it is working Smooth in.

2. For water-cooled, pure water, deionized water or distilled water should be used, non-sticky and often replaced; tap water, mineral water and other liquids containing higher metal ions or other minerals should not be used.

3. The equipment should be well grounded and try to avoid machine vibration.

4. Please don't turn on and off the machine frequently, and it can be turned on after at least 3 minutes after it is turned off.

5. For machines that use casters and foot cups at the same time, after the position of the machine is fixed, please use the foot cups to support the machine. This can ensure the stability of the machine and avoid deformation and damage of the casters caused by long-term pressure.

6. Make sure the heat dissipation of the machine is smooth, and no external heat is allowed to blow directly to the machine.

7. The fluctuation of the power supply grid should be less than 10%. If it cannot be guaranteed, a voltage stabilizer must be installed.

8. If there is any abnormality during operation, the equipment should be shut down immediately, and personnel should be arranged to inspect and maintain the equipment. Please note: The repair should be performed by professionals or authorized personnel from the equipment supplier, and do not disassemble by yourself.