Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

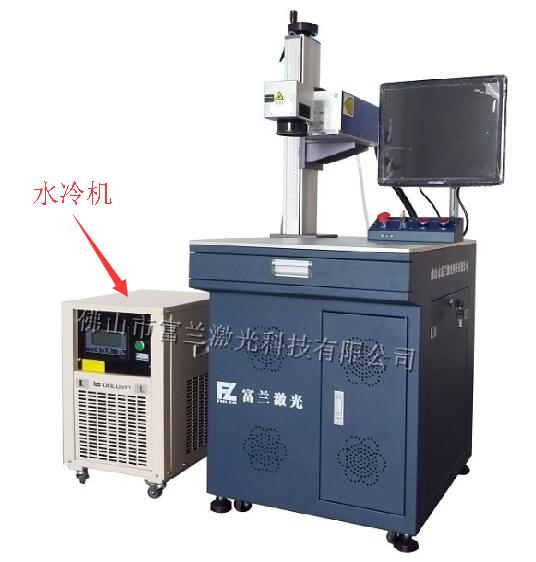

Water chiller is a kind of water cooling equipment, which can provide constant temperature, constant current and constant pressure cooling equipment. The principle of the chiller is to inject a certain amount of water into the internal water tank of the machine, and the water is cooled by the chiller refrigeration system, and then a water pump inside the machine injects low-temperature frozen water into the equipment that needs to be cooled, and the chilled water will heat the internal heat of the machine. Take it away and return the high-temperature hot water to the water tank to cool down again. In this way, it is circulated and exchanged and cooled to achieve the effect of cooling the equipment.

The function of the chiller is to cool the machine transmitter and the Q drive to ensure the normal operation of the laser equipment.

There are two main cooling methods, one is water cooling and the other is air cooling. Generally, equipment with higher laser power (above 50W) uses water cooling; on the contrary, equipment with low laser power (basically no more than 50W) uses air cooling.

The chiller is very important for improving the working accuracy of the laser and ensuring the normal operation of the laser. However, in the daily use of the chiller, due to various factors, it is inevitable that there will be some minor faults. For some simple minor faults, the operator can solve it by himself according to the situation. Therefore, it is very important to understand the faults and solutions of some laser chillers. Necessary. Foshan Fulan Laser Collection has integrated some common faults of laser marking machine chillers and their treatment methods, and share them with you below:

1. Poor cooling effect.

Approach:

1. Check whether the temperature at the installation location of the machine is too high, causing poor heat dissipation. Place the laser marking machine and the chiller in a working environment with a temperature of 15-30°C and a humidity of 45-75%.

2. Check that the condenser fin or filter is dirty, and clean it.

3. The chiller has exceeded its normal service life. The original effect can be restored by replacing the compressor.

4. There may be part of the refrigerant leaking from the system. Replace the refrigerant.

2. The temperature is unstable (far more than the set temperature difference or keep cooling or heating all the time).

Solution: Check whether the power supply voltage is too low.

3. No water flow or small water flow.

Solution: Check whether the air in the water pump is drained, whether the filter at the bottom of the water tank is clogged, whether the capacitor of the water pump is bad, and whether the relay that controls the water pump is closed.

4. High temperature or low temperature alarm.

Approach:

1. Check whether the air in the water system is not completely drained, you can pull out the water outlet to let the water flow out partly, and then start the machine after installation.

2. Whether the filter at the bottom of the water tank is blocked, just clean it.

3. Whether the suction port of the water pump is flat.

4. The water pump itself is stuck and does not rotate or the coil is broken or the capacitance is bad.

5. The water pump has water circulation, and the flow switch is broken if the flow switch is not working.

5. The power supply is normal and the whole machine cannot be operated.

Approach:

1. Check whether the fuse is blown, and replace the spare fuse.

2. Check whether the reverse relay is faulty, and replace the reverse relay.